Lahebo Risk Register Software and Air Monitoring for Silica Dust: Smarter Safety Management for the Future

In Australia’s evolving occupational health landscape, real-time safety intelligence replaces the antiquated reliance on clipboards and scattered spreadsheets. As the monitoring of health regulatory requirements on smoke and toxic dusts heat up, especially respirable crystalline silica, businesses must triangulate health data, exposure monitoring, and compliance monitoring integrated within a single source. Lahebo Lahebo Risk Register software quietly reshapes the digital risk landscape by marrying compliance and health monitoring with self-surveillance silica dust air monitoring systems.

Challenge: Visible Accountability, Invisible Risks

Safe Work Australia is kicking up its risk exposure mitigation strategies. As the revised workplace exposure standard hits 0.05 mg/m³ and the national agenda targets the engineered stone industry, businesses can no longer afford reactive, fragmented, siloed monitoring systems. Silica exposure is a compliance, reputational, and ethical risk that requires unmitigated proactive monitoring system exposure.

It is critical, disconnected systems designed for siloed monitoring is the real compliance risk. Monitoring exposure, record keeping, risk assessment, and corrective action is so slowed that expected handovers lead to measurable data gaps with exposure events exceeding acceptable levels.

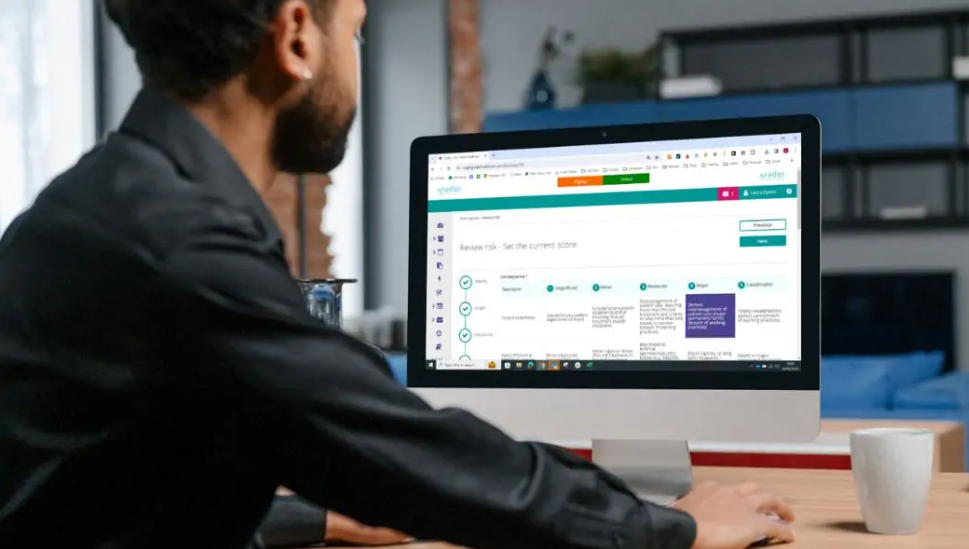

Lahebo’s Risk Register software solution to fragmentation is bringing together environmental, operational, and health data into one platform. It records risks and connects them to real-time evidence and action pathways.

From Static Compliance to Dynamic Monitoring

Predicting and mitigating risks is still working in progress and challenges remain. Existing controls should still be effective, otherwise they should be updated. Until then, the static risk register process should still be applied in some form.

Lahebo’s Risk Register streamlines automation, allowing business owners to risk profile jobs and determine control requirements. Controls should be monitored and evaluated to determine whether they apply and if they are effective.

Linking Exposure to Enterprise Risk

For example, risk and control exposure do not end at the workshop in silica dust case. There are severe exposure incident business impacts, including legal liability, lost productivity, heightened insurance, and long-term work compensation exposure.

Lahebo Risk Register software integrates previously invisible hygiene results into risk visibility across the organization. Take, for instance, air monitoring results. These can be integrated with:

Departmental risk categorizations (like fabrication, cutting, polishing).

Health surveillance records for spotting patterns with results over time.

Action centre items related to engineering controls and PPE reviews.

Legislation references updated automatically with Lahebo legislative library.

The hierarchy and depth on integrated risk results means no air sample, exposure event, or control action is omitted. Every element is accounted for and integrated into the organization’s risk ecosystem. No action is simply a line lost in a report.

See also: Future Trends in Business Tools and Technology

Data that enables accountability and learning

In Australia, the ability to trace actions and show due diligence is critical. Inspectors expect evidence showing not only *what* action was taken, but also when, why, and who executed it.

The digital workflows in Lahebo illustrate this accountability in action. Each risk, for example, silica dust exposure, is defined and tracked, along with unambiguous evidence that documents decision-making. Result: air monitoring for silica dust provides a direct line of accountability.

More importantly, the system intelligently assists businesses with learning. Air quality trend data can be showcased on dashboards, quickly determining the effectiveness of dust suppression and ventilation systems. With data accumulation, this becomes a tactical instrument for strategic guidance, and design decisions can be made well beyond mere compliance for audits.

Integration with ISO and WHS Standards

In Australia, the frameworks surrounding silica risk management comprise ISO 45001 (Occupational Health & Safety), ISO 14001 (Environmental Management), and the Model WHS Regulations. The burden of ensuring these frameworks align stays manual, complex and demanding of resources.

Lahebo solves the problem with standard-aligned frameworks, embedded templates, automated review scheduling, and tracking activities as proof of audits. Once the air monitoring systems registers exposure data, it can be linked to control measures described within ISO 45001 or WHS regulations.

By connecting these frameworks, Lahebo cuts down the time needed to complete admin work and improves audit preparedness, a common requirement for businesses looking to secure government contracts or certifications.

Predictive Safety Intelligence

The aim of monitoring systems, Lahebo argues, should be due predictive capabilities instead. Evolving systems and the integration of new data types will lead to predictive analytics and a true monitor system. Predictive analytics will allow businesses to prevent exposure risks by correlating different systems like environmental factors, silica levels, equipment maintenance schedules, and production volumes.

What makes Lahebo Risk Register software unique is that it provides the foundation for predictive safety intelligence. It provides predictive safety intelligence along with continuous air monitoring for silica dust. This technology allows Australian companies to move from defensive compliance to proactive protective measures—defending against risks before they hurt people or reputations.

Bottom line: Australia’s silica dust problem requires more than sensors and spreadsheets; it requires thinking systems. By placing Lahebo Risk Register software at the core of interlinked systems, organizations are able to change their perspective from compliance to foresight, from a mere defensive compliance culture to active proactive cultural defenses, and from fragile risk to risk resilience. This is more than software; it is responsible, intelligent, and data-driven safety management that Australia has needed for a long time.