The Unsung Hero: A Comprehensive Look at Motor Shafts in Modern Industry

Introduction

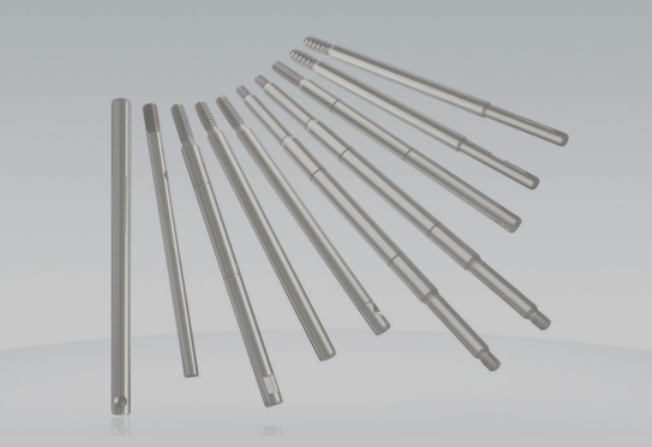

The motor shaft, seemingly a simple cylindrical component, forms the backbone of countless electric motors that power our modern world. Protruding from the heart of the motor, the shaft serves as the crucial link that transmits the electrical energy generated into usable rotational motion, delivering torque to an astonishing array of applications. From the sophisticated machinery driving industrial automation to the everyday appliances that simplify our lives, and the cutting-edge advancements in electric vehicles and aerospace, the motor shaft plays an indispensable role. Its function in converting electrical power to kinetic energy is fundamental to the operation of electric motors.

The importance of motor shafts extends across a remarkably diverse range of industries. In the automotive sector, including the rapidly expanding realm of electric vehicles, motor shafts are integral to propulsion systems, ensuring the wheels turn and the vehicle moves. They are found in critical components like crankshafts, camshafts, and the very shafts that drive electric motors. The aerospace industry, with its relentless pursuit of efficiency and performance, relies on high-precision motor shafts in actuation systems, landing gear, and even within the engines themselves. Industrial automation, the driving force behind modern manufacturing, depends on robust and reliable motor shafts to power conveyor systems, robotic arms, and a multitude of other automated processes. Even within our homes, motor shafts are at work in appliances like fans, pumps, and power tools. The proper functioning of these shafts is not merely a matter of operational efficiency; it directly impacts the safety, performance, and ultimately, the longevity of the machinery they serve. A seemingly minor component, the motor shaft is truly an unsung hero of modern technology, and its reliable performance hinges on the precision and quality embedded in its very creation.

Material Matters: A Deep Dive into Motor Shaft Materials

The selection of the appropriate material for a motor shaft is a critical decision, one that directly influences the shaft’s performance and lifespan. Engineers must carefully consider a multitude of factors, including the strength required to transmit torque, the toughness needed to withstand operational stresses, the material’s resistance to wear and corrosion, its machinability for precise shaping, and, of course, the overall cost-effectiveness. The specific demands of the intended application often dictate the priority of these properties.

Among the most commonly employed materials for motor shafts are various steel alloys. Carbon steel, such as SAE 1045, offers a good balance of strength, toughness, wear resistance, and machinability, making it a cost-effective choice for many general-purpose applications. For more demanding applications that require enhanced performance, alloy steels like 4140 and 4340 are frequently utilized. The addition of alloying elements such as chromium, nickel, and molybdenum significantly improves the steel’s strength, hardness, and resistance to wear, making these alloys ideal for heavy-duty and high-stress environments.

In applications where resistance to corrosion is paramount, stainless steel stands out as an excellent material choice. Various grades of stainless steel, such as 303, 304, 316, and 416, offer different combinations of machinability and corrosion resistance to suit specific needs. These materials find widespread use in industries like marine, medical, and food processing, as well as in automotive applications where exposure to moisture or corrosive substances is a concern.

For applications where weight is a critical factor, such as in the aerospace industry and the burgeoning electric vehicle market, aluminum alloys provide a compelling alternative. Grades like 6061 and 7075 are commonly employed in aerospace and high-performance automotive applications.

The pursuit of even lighter and higher-performing motor shafts has led to the increasing adoption of composite materials. Carbon fiber and fiberglass composites offer exceptional strength-to-weight ratios and excellent corrosion resistance. These advanced materials are finding growing use in aerospace components and in automotive applications, particularly in the development of lightweight and efficient drive shafts for electric vehicles.

Table 1: Comparison of Common Motor Shaft Materials

| Material Type | Typical Applications | Key Properties |

| Carbon Steel (SAE 1045) | General industrial motors, pumps, axles | Good strength, toughness, wear resistance, machinability |

| Alloy Steel (e.g., 4140) | Heavy-duty machinery, gears, high-stress automotive parts | Enhanced strength, hardness, wear resistance |

| Stainless Steel (e.g., 304) | Marine, medical, food processing, corrosive environments | Excellent corrosion resistance, good strength, durability |

| Aluminum Alloy (e.g., 6061) | Aerospace, automotive (lightweight components) | Lightweight, corrosion-resistant, good strength |

| Carbon Fiber Composite | Aerospace (transmission shafts), EV drive shafts | High strength-to-weight ratio, corrosion resistance, design flexibility |

Precision Engineered: The Art and Science of CNC Machining Motor Shafts

The dominant manufacturing process for motor shafts is Computer Numerical Control (CNC) machining. This sophisticated subtractive manufacturing technique utilizes computer-controlled machine tools to meticulously remove material from a workpiece, ultimately shaping it into the desired motor shaft with remarkable accuracy.

CNC machining offers exceptional precision and accuracy, often within a few thousandths of an inch, crucial for proper motor shaft function. Automation allows continuous operation with minimal human intervention, increasing production speed and efficiency. Its versatility enables the production of various shapes and sizes from different materials with intricate designs. Common CNC techniques include turning for cylindrical shapes, milling for features like keyways, grinding for fine finishes, drilling for holes, and EDM for intricate shapes in hard materials. The integration of CAD/CAM software enhances efficiency and accuracy by translating digital designs into machine instructions.

Powering the World: Diverse Applications of Motor Shafts

Motor shafts are the driving force behind a vast array of machinery across numerous sectors. In the automotive industry, including electric vehicles (EVs), they are critical in engine, transmission, and drivetrain assemblies. EVs demand lightweight shafts with excellent dynamic balance. The aerospace industry requires motor shafts in aircraft engines, actuation systems, and landing gear, capable of withstanding extreme conditions. High strength and lightweight construction are paramount, often utilizing materials like titanium alloys and composites. Industrial automation relies on motor shafts in robotics and manufacturing equipment, demanding high precision and durability for continuous operation.

Read also: How IPTV Works: A Beginner’s Guide to Understanding IPTV Technology

Setting the Standard: Quality and Precision in Motor Shaft Manufacturing

Ensuring the quality and precision of motor shafts is paramount. In Europe, ISO 2768 and ISO 286 are widely used for general and specific tolerances, respectively. The United States commonly utilizes ASME standards like ASME Y14.5 and ASME B4.1. NEMA standards also play a role in defining motor frame sizes and related specifications in the US. Surface finish, often measured by Ra values, is crucial for performance, affecting friction and wear. Different applications have varying surface roughness requirements. Advanced measurement tools like CMMs and laser scanners are essential for quality control, with a trend towards in-process inspection for real-time feedback.

Table 2: Typical Surface Roughness (Ra Values) for Motor Shafts in Different Applications

| Application | Ra Value (µm) | Ra Value (µin) |

| Bearing Journals | 0.2 – 1.6 | 8 – 63 |

| Fitting Journals | 0.4 – 3.2 | 16 – 126 |

| Automotive Crankshaft Main Journal Bearing | – | 4 – 6 |

| Automotive Piston Pin (Diesel Engine – Fine Finish) | – | 4 |

| Aerospace HVOF Applied Coatings | 0.05 – 0.10 | 2 – 4 |

| Aerospace Anodized Surfaces (Internal Seals) | 0.10 – 0.20 | 4 – 8 |

The Drive for Improvement: Efficiency and Cost Reduction Strategies

Improving efficiency and reducing costs are continuous goals in motor shaft manufacturing. Optimizing CNC machining parameters, such as speed and feed rate, is crucial. Implementing lean manufacturing principles, like 5S and JIT, helps eliminate waste and streamline production. Strategic material procurement and inventory management, including selecting near-net-shape materials and utilizing JIT systems, are also vital. Some companies have successfully reduced costs by changing manufacturing methods, such as switching from all-cutting to cold forging combined with rolling.

A Sustainable Future: Environmental Considerations in Motor Shaft Manufacturing

Sustainability is increasingly important in motor shaft manufacturing. Efforts include improving the energy efficiency of CNC equipment and processes by using energy-saving machines and optimizing parameters. Reducing material waste through optimized design and recycling programs is also key. The use of environmentally friendly cutting fluids and materials, such as biodegradable options and MQL systems, minimizes environmental impact. Compliance with environmental regulations like the EU’s Industrial Emissions Directive and the US EPA’s regulations is essential. Many companies are adopting sustainable manufacturing practices, including using renewable energy and recycling.

Looking Ahead: Emerging Trends in Motor Shaft Technology

The future of motor shaft technology is being shaped by several emerging trends. Advancements in CNC machining include multi-axis machines, AI and machine learning integration for process optimization and predictive maintenance, and increased automation and robotics. Material trends point towards the increased use of lightweight materials like advanced aluminum alloys and composites. Hollow shaft designs are gaining popularity, especially in electric vehicles. The concept of smart motor shafts with integrated sensors for real-time performance data is also emerging. Sustainability will continue to drive innovation, with a focus on energy-efficient manufacturing processes and recyclable materials. The integration of Industry 4.0 principles, including IoT and digital twins, will further enhance efficiency and intelligence in motor shaft production.

A Transatlantic Perspective: Comparing Motor Shaft CNC Machining in Europe and the US

Both Europe and the United States have advanced CNC machining capabilities for motor shafts. Some perceive Europe as slightly ahead in automation and multi-axis machining, potentially due to leading control system manufacturers like Siemens and Heidenhain being based in Germany. The US market has strong players like Haas, focusing on cost-effective and user-friendly machines. While the US has a larger overall manufacturing output, Germany has a higher percentage of its workforce in manufacturing. The cost of CNC machining services can sometimes be higher in Europe. Overall, both regions have high technological levels, with some differences in emphasis based on industry structure and market demands.

Conclusion: The Enduring Importance of Precision in Motion

The motor shaft remains a critical component across numerous industries. Its seemingly simple function relies on complex considerations of material selection, precision manufacturing, and stringent quality standards. As technology advances, demands on motor shafts will intensify, driving innovation in materials, designs, and manufacturing processes. The increasing focus on efficiency and sustainability will further shape the industry’s future. Emerging trends like AI-powered machining and advanced composite materials promise even greater performance and reliability. The enduring importance of precision engineering underscores the foundational role of the motor shaft in powering our world.

And if you’re curious to dig deeper, parts of this piece drew inspiration from an insightful article by the folks at motor-shaft-customization-why-cnc-machining-is-the-best-option click here to explore more on how motor shafts analysis are reshaping manufacturing.

FAQ:

1: What is a motor shaft?

A: A motor shaft is a cylindrical component that extends from an electric motor, transmitting the motor’s power into rotational motion for various applications . It’s a crucial link between the motor’s energy generation and the work it performs .

2: What materials are commonly used for motor shafts?

A: Common materials include carbon steel for general applications due to its balance of strength and cost . Alloy steels like 4140 and 4340 are used for higher strength and demanding environments. Stainless steel is chosen for its corrosion resistance in applications exposed to moisture or chemicals . Aluminum alloys are used when weight is a critical factor, such as in aerospace and electric vehicles . Composite materials like carbon fiber offer a high strength-to-weight ratio for specialized applications .

3: What is CNC machining and why is it used for motor shafts?

A: CNC (Computer Numerical Control) machining is a precise manufacturing process that uses computer-controlled machines to remove material from a workpiece to create the desired shape . It’s preferred for motor shafts due to its high accuracy, repeatability, efficiency, and ability to produce complex geometries

4: What are the advantages of CNC machining for motor shafts?

A: Advantages include high precision and accuracy , consistent quality and repeatability , the ability to create complex designs , increased production speed and efficiency , reduced material waste , and the flexibility to work with various materials .

5: What are the quality standards for CNC machined motor shafts in Europe and the US?

A: In Europe, ISO 2768 and ISO 286 are commonly used standards for general tolerances and fits . In the US, ASME standards like ASME Y14.5 and ASME B4.1 are prevalent, along with NEMA standards for motor frame dimensions . These standards ensure dimensional accuracy and proper fit .

6: What are the surface finish requirements for motor shafts?

A: Surface finish is critical for performance, affecting friction, wear, and sealing . Requirements vary by application; for example, bearing journals typically need a smoother finish (Ra 0.2-1.6 µm) than fitting journals (Ra 0.4-3.2 µm) . Aerospace applications often have very specific and stringent requirements .

7: What are some innovative CNC machining techniques for motor shafts?

A: Advanced techniques include multi-axis CNC machining for complex shapes , high-speed machining for increased efficiency , and the integration of AI and machine learning for process optimization and predictive maintenance . Other innovative processes include CNC grinding for precise finishes , CNC turning for cylindrical parts , and CNC milling for features like keyways and splines .

8: How is automation used in motor shaft production?

A: Automation is increasingly used for tasks like material handling, loading and unloading machines, tool changes, and quality inspection . This reduces labor costs, increases efficiency, and allows for continuous operation .